Maximum durability. Superior quality.

Custom crossflow heat exchangers tailored to your application

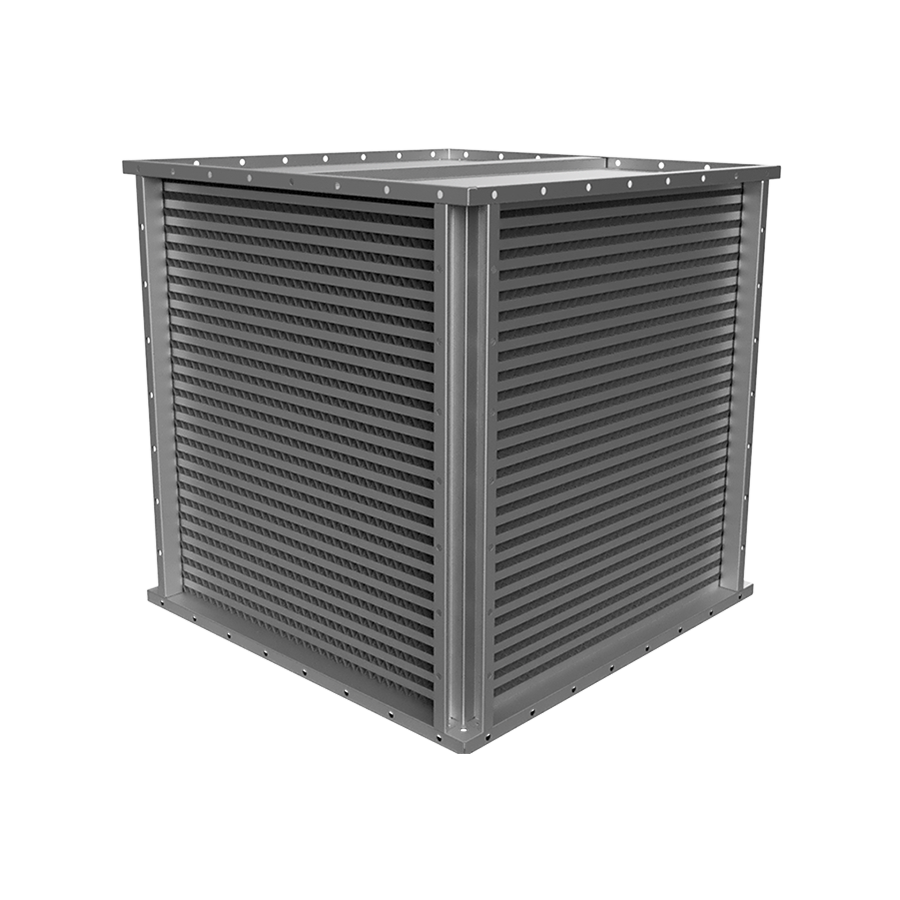

Industrial processes involve extreme conditions: paints, acids, exhaust gases, brine, high temperatures, and constant humidity place continuous demands on materials and workmanship. POLYBLOC plate heat exchangers are built to withstand these challenges – thanks to the highest manufacturing precision, custom dimensions, variable plate spacing, and a wide selection of materials ranging from stainless steel and aluminum to plastic. Their high temperature resistance and application-specific design ensure maximum efficiency, durability, and energy savings – making them the ideal solution for air-to-air and gas-to-gas heat transfer applications.

Materials and Applications

Typical application areas include laboratories, electroplating plants, paint shops, brine baths, industrial catalysts, waste heat recovery systems, and CO₂ capture plants – essentially anywhere reliable heat transfer of gaseous media is required under demanding conditions.

For highly corrosive process air streams, specially designed crossflow heat exchangers made from coated aluminum, plastic, or stainless steel are used. Among these, stainless steel offers the best solution for applications involving high temperatures – such as in exhaust gas heat exchangers.

Particularly in the recovery of process heat, POLYBLOC heat exchangers can help realize significant energy savings. Thanks to their robust design and high efficiency, the investment often pays for itself in less than a year.

For especially demanding applications requiring high tightness and temperature resistance, our gas-tight stainless steel exchangers are welded using a precise microplasma process.

Referenzprozesse

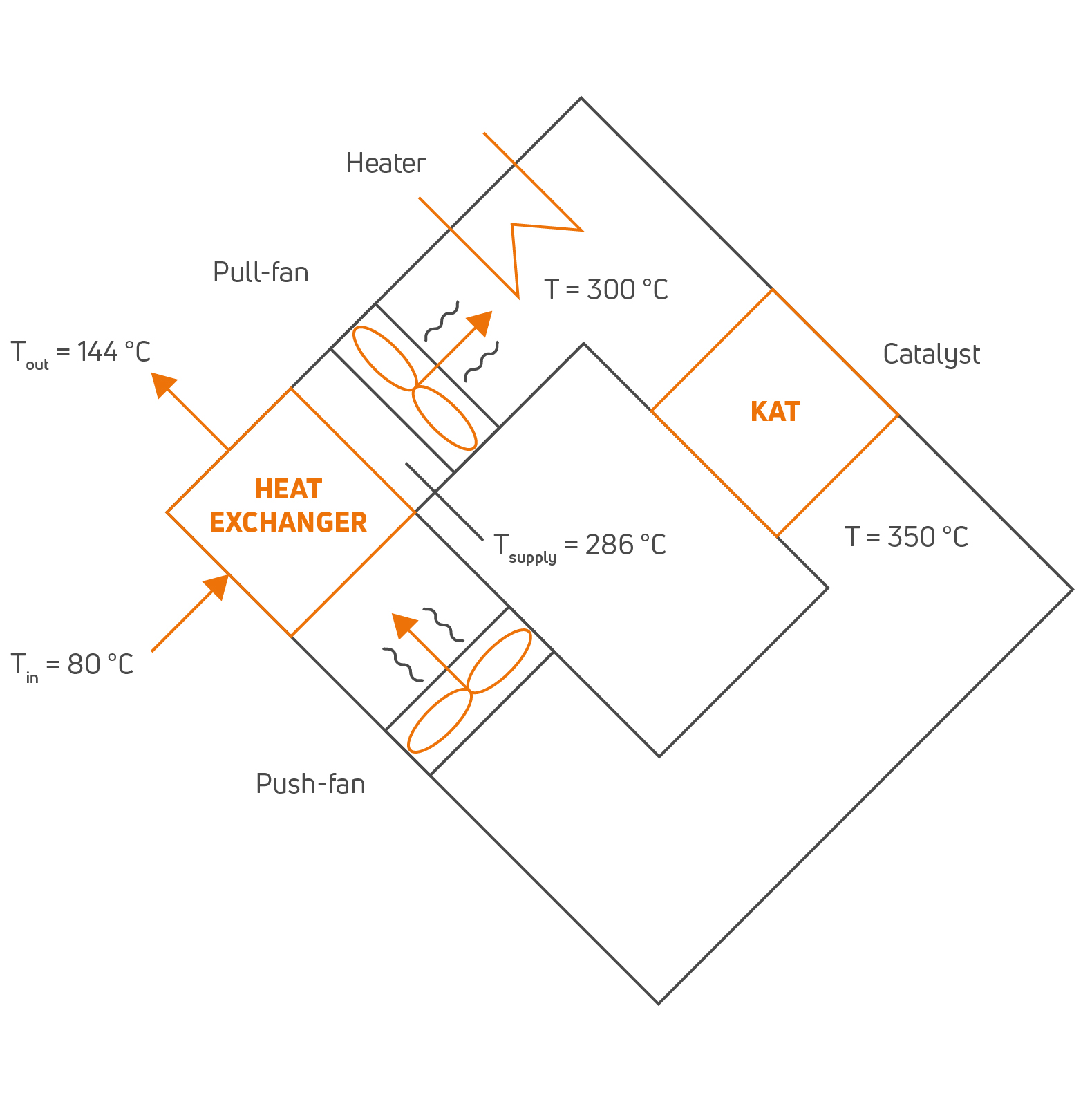

The exhaust gas to be cleaned is first preheated by the exhaust air flow before entering the catalytic cleaning process. A heater raises the exhaust gas to the required reaction temperature. In the catalytic converter, the exhaust gas undergoes an exothermic reaction. The purified exhaust air, now at an elevated temperature, transfers its energy to the colder supply air via a heat exchanger, achieving efficiencies of up to 80%.

Process diagram based on hypothetical conditions. Limit conditions of the stainless steel plate heat exchanger:

Tmax = 800°C

ΔPmax, GD version = 0.25 bar

ΔPmax, non-GD version = 0.1 bar

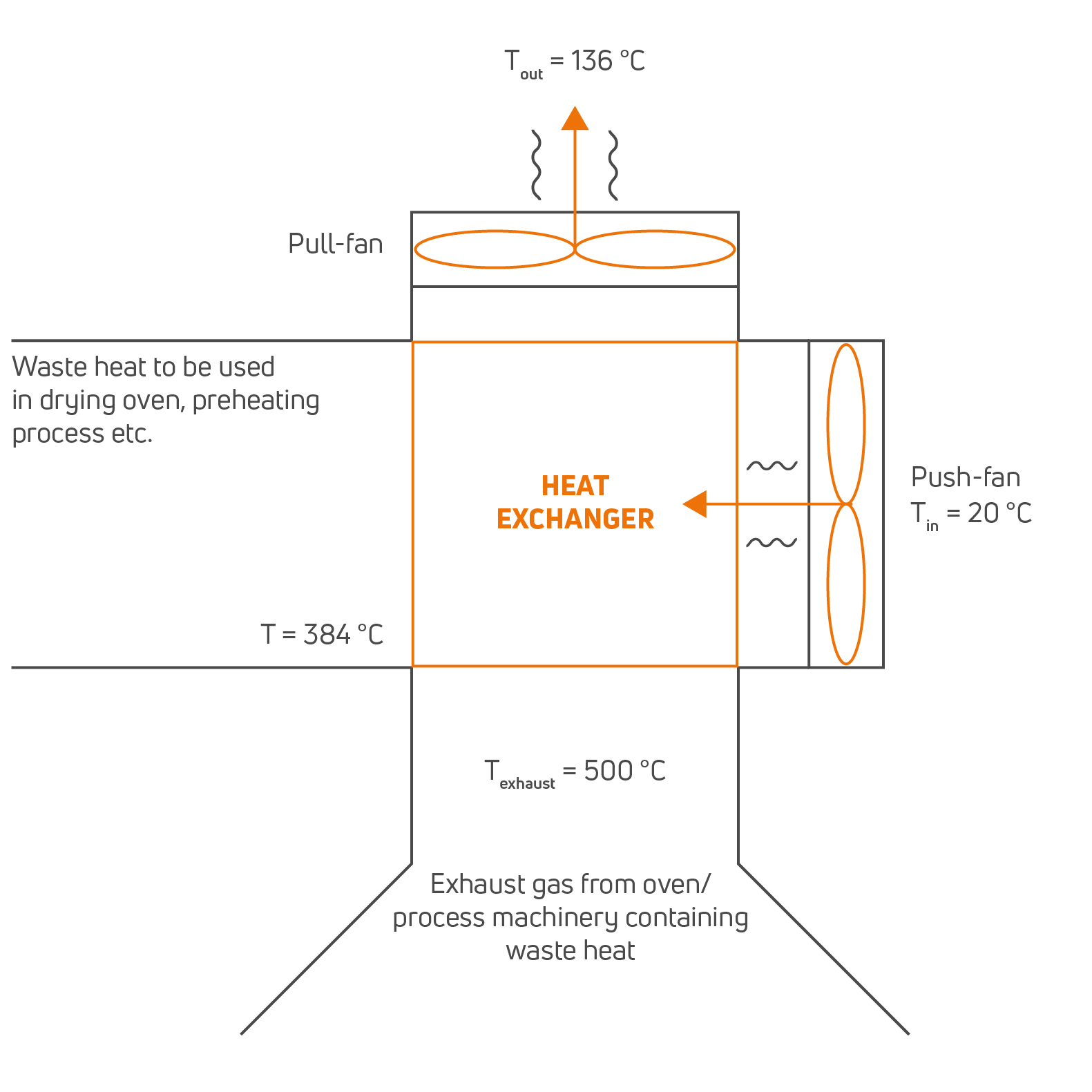

In this process, the hot exhaust gas from an energy system is directed into a heat exchanger. The exchanger is used to preheat fresh air, which can subsequently be utilized in downstream applications, such as an industrial drying system or a heating system.

Process diagram based on hypothetical conditions. Limit conditions of the stainless steel plate heat exchanger:

Tmax = 800°C

ΔPmax, GD version = 0.25 bar

ΔPmax, non-GD version = 0.1 bar

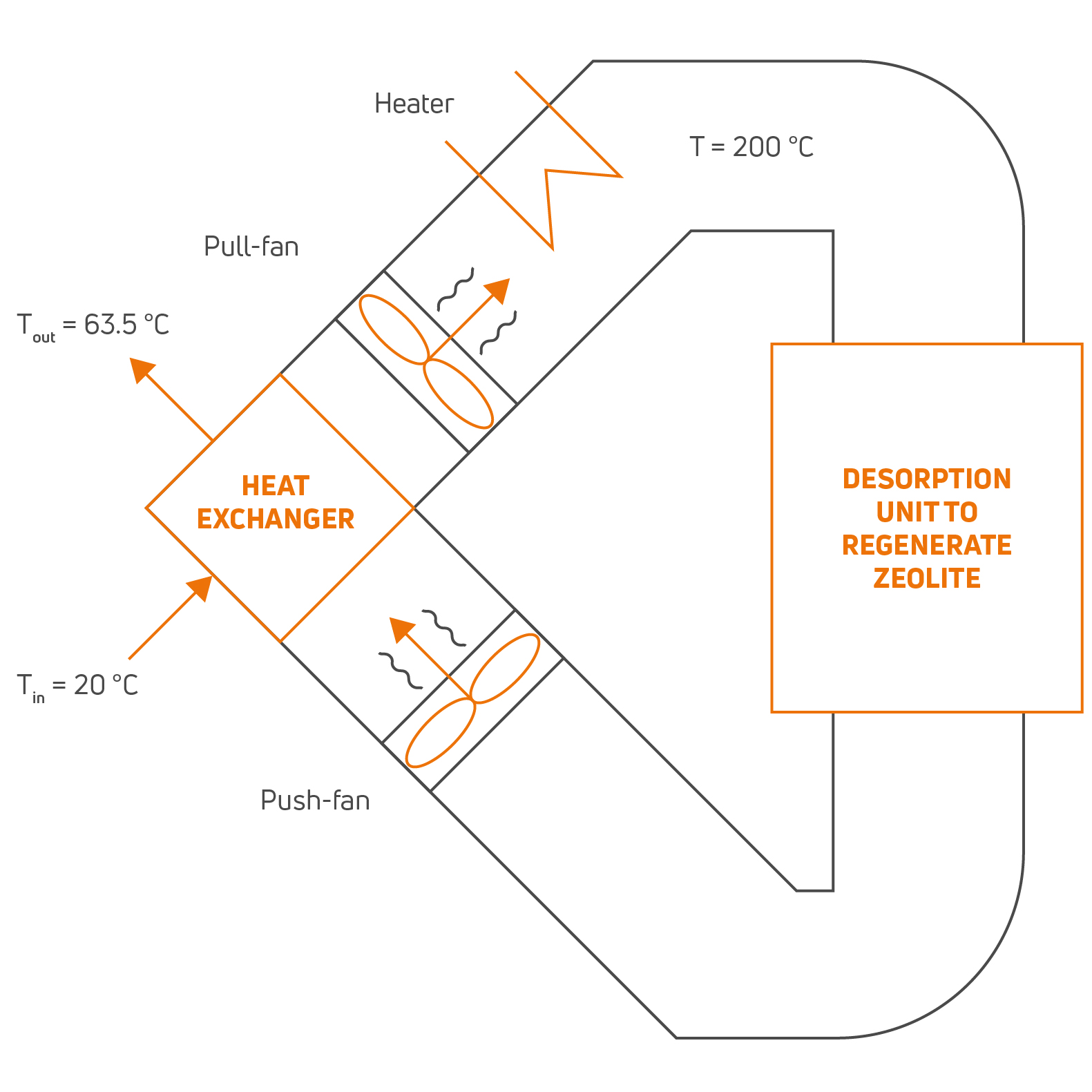

The desorption unit contains zeolite, whose surface has been saturated with CO₂ during the absorption process to produce low-CO₂ air. To regenerate the zeolite, the bound CO₂ must be released. This is achieved by heating air via a heat exchanger, raising it to the required temperature using a heater, and then directing it into the desorption process.

Process diagram based on hypothetical conditions. Limit conditions of the stainless steel plate heat exchanger:

Tmax = 800°C

ΔPmax, GD version = 0.25 bar

ΔPmax, non-GD version = 0.1 bar